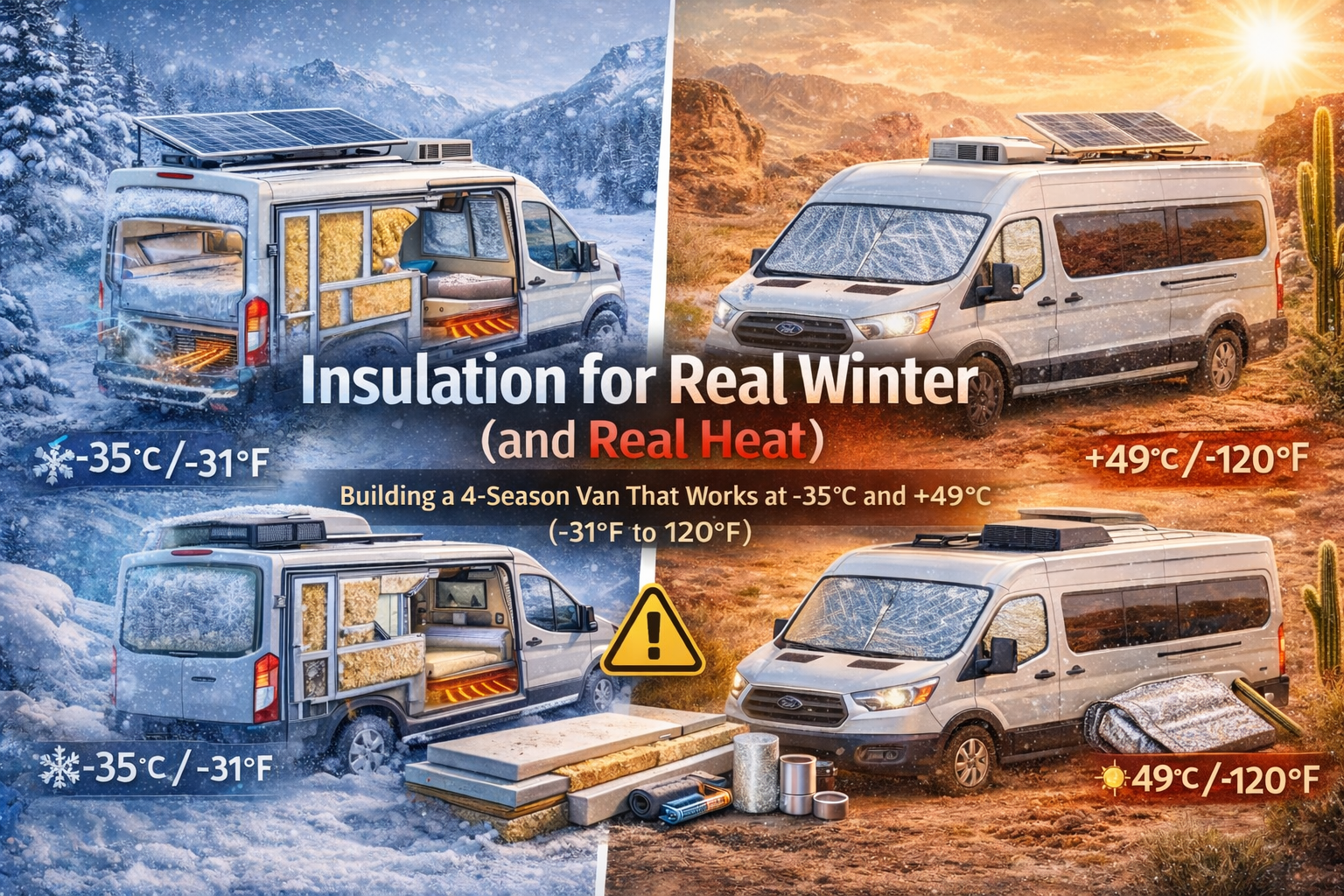

Insulation for Real Winter Van Use (and Real Summer)

A No-Nonsense Van Envelope That Works at –35 °C and +49 °C (–31 °F to 120 °F)

Most van insulation advice is built around mild climates. A “cold night” is 20°F. Condensation is a foggy window.

That advice breaks down completely when you’re parked on the Canadian prairies at –35 °C with wind, or in Arizona in July at 120°F.

This article outlines a hybrid insulation system that:

-

Survives true prairie winter

-

Handles hot desert summer

-

Manages condensation instead of pretending it won’t happen

-

Avoids spray foam risks (panel warping, trapped moisture)

-

Still allows you to mount cabinetry safely

We’ll assume:

-

2026 Ford Transit AWD High Roof Extended

-

Minimal windows (1 sliding door window, 1 rear-side awning window, 1 bed skylight)

-

No bulkhead between cab and living space

-

Radiant floor + hydronic heat + fan coils

-

Mini-split AC + roof fan

The Core Truth (Before Materials)

Heat loss and condensation are driven by air movement first, insulation second.

If warm, moist interior air can reach cold metal:

-

It will condense

-

It will rot things

-

R-value won’t save you

So this system is built around four principles:

-

Airtight to the metal skin

-

Continuous insulation across ribs

-

Moisture-tolerant materials

-

Controlled drying paths (ventilation + temperature control)

Target Performance (Realistic, Not Marketing Numbers)

| Surface | Effective Target (after thermal bridging) |

|---|---|

| Roof | R-12 to R-15 |

| Walls | R-10 to R-13 |

| Floor | R-10 to R-20 |

| Windows | Minimize + insulated covers |

This is excellent performance in a van. Going higher yields diminishing returns unless you also reduce glass and air leakage.

The Hybrid Assembly (No Spray Foam)

WALL ASSEMBLY (Exterior → Interior)

1. Metal Skin (Factory)

-

Already a Class I vapor barrier

-

Cannot dry outward

-

Must never be exposed to interior air

2. Thin Thermal Break on Ribs (Critical)

Material:

-

1/8”–1/4” closed-cell foam tape (EVA / EPDM / Armaflex)

Why:

Steel ribs conduct cold directly inward. This isolates interior framing and prevents “ghost condensation lines.”

3. Continuous Foam Layer (Primary Control Layer)

Material options (pick one):

-

Polyiso rigid board (best R per inch, warm climates)

-

XPS rigid board (better cold-temp performance, more moisture tolerant)

Thickness:

-

1”–1.5” ideal

Install method:

-

Cut tight

-

Adhere to metal with low-expansion adhesive (not spray foam)

-

Seal every seam with foil tape or compatible sealant

👉 This layer does 80% of the work:

-

Air barrier

-

Thermal barrier

-

Vapor control

4. Cavity Fill (Secondary Insulation)

Material:

-

Thinsulate SM600L or

-

Mineral wool (if well restrained)

Purpose:

-

Adds R-value

-

Dampens sound

-

Tolerates moisture without collapsing

⚠️ This layer must not be relied on for air sealing.

5. Interior Service Layer (Mounting + Wiring Zone)

Material:

-

1/2” plywood or composite panels mounted to isolated furring

This creates:

-

A place to run wires

-

A mounting surface

-

No fasteners through the foam into metal

6. Interior Finish

-

Paneling, fabric, or composite

-

Permeable is fine — drying is inward, not outward

ROOF ASSEMBLY (Same Philosophy, Higher Priority)

Roofs fail first in winter.

Upgrade from walls by:

-

Increasing foam thickness to 1.5”

-

Paying extreme attention to fan/skylight cutouts

-

Adding insulated plugs for every opening

FLOOR ASSEMBLY (Wind-Exposed, Do Not Skimp)

1. Factory Metal Floor

-

Seal every penetration

-

No exposed fasteners

2. Continuous Rigid Foam

-

1.5”–2” XPS or Polyiso

-

Seams sealed

-

No gaps at edges

3. Radiant Floor Plates + PEX

-

Aluminum transfer plates improve comfort and efficiency

-

Radiant floor ≠ primary heat source (comfort layer)

4. Subfloor (Plywood or Composite)

-

Mechanically fastened only to isolated hard points

-

Never crush foam unintentionally

WINDOWS, VENTS & SKYLIGHT — PRESSURE TESTED

Windows are the weakest point. That’s okay if you treat them honestly.

Your Window Set (Good Choice)

-

1 sliding or awning door window

-

1 rear-side awning window

-

1 bed skylight

-

Front cab glass (unavoidable)

What This Requires:

WINTER (-35 °C)

-

Interior insulated window plugs

-

Reflectix alone is not insulation

-

Use multi-layer: foam + radiant + air gap

-

-

Magnetic or compression-fit covers

-

Skylight plug is mandatory

-

Expect some condensation → manage it

SUMMER (120 °F)

-

Exterior reflective covers

-

Stop solar gain before it enters

-

-

Interior covers alone are not enough

-

Roof fan + mini-split must exhaust heat

Cab Integration (No Bulkhead)

This increases:

-

Heat loss

-

Cooling load

But also:

-

Improves airflow

-

Reduces condensation dead zones

Required upgrades:

-

Insulated windshield + cab window covers (winter & summer)

-

Controlled airflow from rear to front

-

Do not rely on factory dash HVAC for rear comfort

Does This System Work in Arizona?

Yes — and better than most builds.

Why:

-

Continuous foam limits heat soak

-

Reduced glass limits solar gain

-

Mini-split + roof fan removes heat efficiently

-

Interior materials tolerate high temp swings

Key summer additions:

-

Exterior window covers

-

Light-colored roof finish (or coating)

-

Shading whenever possible

Materials Shopping List (High Level)

Insulation & Air Control

-

Polyiso or XPS rigid foam boards

-

Foam tape for ribs

-

Foil HVAC tape (UL listed)

-

Low-expansion adhesive

-

Thinsulate or mineral wool

Windows & Covers

-

Insulated window plug materials

-

Exterior reflective covers

-

Skylight insulated insert

Mounting & Structure

-

Isolated furring strips

-

Rivnuts or bonded hard points

-

Plywood service panels

DO NOT DO THIS (Seriously)

❌ Spray foam directly on large exterior panels

❌ Leave steel ribs unbroken

❌ Install interior poly vapor barrier

❌ Rely on Reflectix alone

❌ Fasten cabinetry through insulation into metal

❌ Assume condensation “won’t be an issue”

Attaching Furniture Without Breaking the System

Rule:

Furniture mounts to structure, not skin.

Best methods:

-

Bonded hard points

-

Rivnut rails isolated with foam tape

-

Floor-anchored cabinetry tied into subfloor

This preserves:

-

Airtightness

-

Thermal continuity

-

Serviceability

Final Takeaway

This insulation strategy is:

-

Cold-climate legitimate

-

Moisture tolerant

-

Summer capable

-

Repairable and inspectable

-

Compatible with hydronic radiant heat

It is not the lightest, cheapest, or fastest.

But it is what holds up when the wind is howling at –35 °C — and when you’re parked in Arizona wondering why everyone else’s van feels like an oven.

Sign up with your email and always get notifed of Avada Lifestyles latest news!