Coming down the road, literally… the MADCTY Van Build

There’s been a long-standing dream in the background of my life for years now.

A van. Not just a van—but a camper van that could take me anywhere. A space I could stand up in, sleep comfortably in, and live out of for days at a time without worrying about shore power, weather, or seasons. A rig that could handle heat, cold, shoulder seasons, and everything in between. A van that wasn’t fragile or fair-weather—something genuinely capable.

For a long time, that dream lived in the form of YouTube videos watched with curiosity. Van tours. Build breakdowns. “What I’d do differently” retrospectives. Interesting, inspiring—but abstract.

That changed the moment I ordered the foundation.

I’ve officially ordered a Ford Transit T350 High Roof Extended (H3L4) Cargo Van in Carbonized Grey Metallic. And with that single decision, everything shifted.

Suddenly, this isn’t about hypotheticals. It’s about design decisions, engineering trade-offs, and committing to systems that will define how this van lives—year-round, off-grid, and across continents.

The Shift: From Inspiration to Engineering

Almost overnight, my relationship with van life content changed.

I stopped watching videos passively and started dissecting them:

-

Why this insulation method?

-

Why that heating system?

-

What happens when temperatures hit -30°C?

-

How does condensation behave over weeks, not weekends?

-

Can this electrical system realistically support air conditioning, cooking, and work—simultaneously?

My search history went from “van life tour” to “Transit H3L4 hydronic radiant floor heat”, “48V camper electrical architecture”, and “four-season vapor-tolerant insulation strategies.”

And honestly—my head started reeling.

There’s an overwhelming amount of beginner-level content out there, mixed with genuinely advanced concepts that only make sense once you understand the fundamentals. I found myself constantly looping:

-

Learn the concept

-

Realize I don’t fully understand it

-

Go back and research the physics

-

Then research real-world implementation

Rinse and repeat.

Leveraging AI as a Research Partner

One thing I’m deeply thankful for is that I’m building this in an era where AI tools exist—not as answer machines, but as research collaborators.

Being able to:

-

Ask questions in natural language

-

Challenge assumptions

-

Request deeper explanations when something doesn’t click

-

Re-run the same problem through a different lens

…has been transformative.

The quality of answers is directly tied to the quality of the questions you ask—and learning how to ask better questions has become part of the build process itself. Every subsystem I explore opens up three more lines of inquiry, and instead of being paralyzed by that, I’m learning to work through it methodically.

Where the Design Has Landed (So Far)

After months of general inspiration and a very intense week of platform-specific research, here’s where the vision is solidifying.

This van is being designed as a true four-season, off-grid, long-range platform, not a weekend toy.

1. Electrical System: Built for Real Power, Not Just Lights

This build assumes modern electrical demands:

-

Air conditioning (including the possibility of extended runtime)

-

Induction cooking

-

High-draw appliances (air fryer, kettle, coffee gear)

-

Workstation power

-

Simultaneous loads without “one thing at a time” rules

Key principles shaping the electrical architecture:

-

Large battery capacity with fast charge acceptance

-

Heavy reliance on alternator charging, not just solar

-

Shore power flexibility (15A / 30A / 50A where available)

-

Consideration of 24V vs 48V architectures to reduce current, heat, and cable bulk

This isn’t a minimalist system—it’s an intentional one. The goal is resilience, efficiency, and headroom rather than living at the edge of capacity.

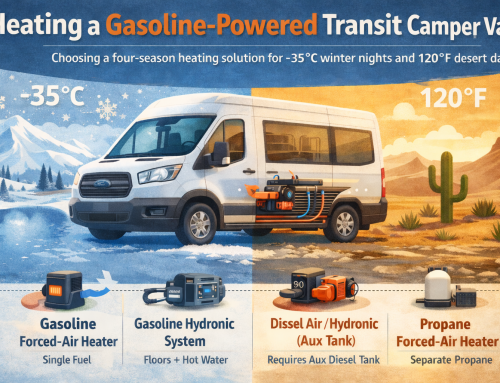

2. Heating & Hot Water: Hydronic, Integrated, Redundant

For true four-season use—especially Canadian prairie winters—forced air alone doesn’t cut it.

The heating strategy centers around a gasoline hydronic system that provides:

-

Radiant floor heating (comfort + efficiency)

-

Continuous hot water

-

Engine heat integration (waste heat recovery while driving)

-

Multiple heat exchanger loops for redundancy

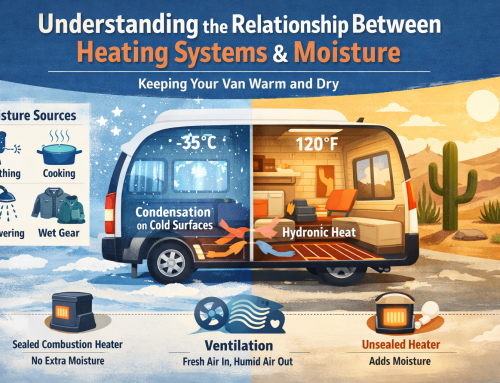

Radiant floor heat isn’t just about comfort—it changes how the van dries out, how condensation behaves, and how livable the space feels in extreme cold. Warm floors, warm surfaces, and consistent heat distribution matter when you’re not chasing sunny climates.

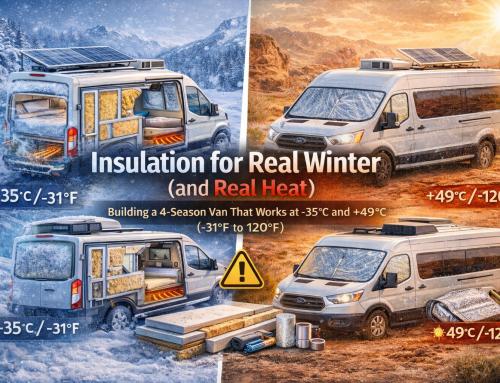

3. Insulation: Designed for Cold and Moisture

This is one of the most misunderstood areas of van builds—and one of the most critical.

The insulation approach is being shaped by a few hard requirements:

-

Performance at -25°C to -35°C

-

Moisture tolerance for coastal rainforest use

-

No reliance on “perfect vapor barriers” that inevitably get compromised

-

Realistic condensation management over weeks, not days

The focus isn’t just R-value—it’s system behavior:

-

Air sealing vs vapor control

-

Thermal bridging mitigation

-

Materials that don’t trap moisture against steel

-

Assemblies that can dry, not just resist

This is insulation for reality, not Instagram.

4. Layout & Livability: Space That Works Every Day

The Extended Transit platform enables a few non-negotiables:

-

Standing room for a 6’3” human—with finished floors and ceilings

-

A north-south bed without gymnastics

-

A fully enclosed shower and toilet space

-

Mechanical systems that are serviceable, not buried

This van needs to function as a home, a workshop, a basecamp, and eventually—proof of concept.

Where I’m At Right Now

I’m still early in the build timeline—but mentally, I’m already deep in it.

I’ve moved past dreaming and into designing. Past inspiration and into trade-offs. Past “what looks cool” and into “what works when it’s -30°C and dark at 4pm.”

The foundation is ordered. The questions are getting sharper. The systems are starting to take shape.

And this—this is where the real work begins.

More to come.

Sign up with your email and always get notifed of Avada Lifestyles latest news!